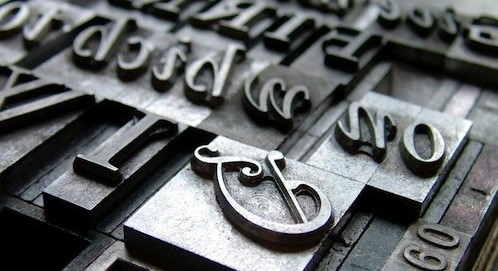

(i) Also known as typographic printing, since 13th century, it is one of the oldest printing techniques in practice. It is a commercial printing technique where many copies of an image are produced by repeated, direct impression of an inked, raised surface against sheets or a continuous roll of paper. Here, the image or printing areas are raised above the non-printing areas; the process involves printing images by the “relief” type printing plates. Rollers are laden with ink and they pass it to a separate ink bed; a fresh film is picked here for the following sheet of paper. A sheet of paper is pressed onto a type, swung back again and finally removed. A new sheet or roll of paper is again inserted at this place. Two types of letterpress printing machines are there- Flat bed cylinder Machines and Rotary letterpress printing machines.

(a) Flat-bed cylinder- an inking roller and an ink fountain supply ink to the plate cylinder. The plate is locked to a horizontal or vertical bed, which passes over the inking roller and then against the substrate. As the substrate moves from the feed stack to the delivery stack, it passes around an impression cylinder. In other words, a single revolution of the cylinder moves over the bed while in a vertical position so that both the bed holding the substrate and cylinder move up and down in a reciprocating motion. Either one or two-color impressions can be printed by Flat-bed cylinder presses, which operate in a manner similar to the platen press and print stock as large as 42 inches by 56 inches. These presses operate very slowly with an hourly production rate of not more than 5,000 impressions. For this reason, much of the printing initially done by this type of press is now being carried out by rotary letterpress or lithography.

(b)Rotary Letterpress Printing- requires curved image carrying plates. The most popular types of plates used are stereotype, electrotype, and molded plastic or rubber. These presses use heat-set inks and are equipped with dryers, usually the high-velocity hot air type, when printing on coated papers. These are of two types- sheet-fed and web-fed. The use of the former has been declined while the latter presses are the most popular type of letterpress printing. They are used primarily for printing newspapers. These presses are designed to print both sides of the web simultaneously. Typically, they can print up to four pages across the web; however, some of the new presses can print up to six pages across a 90-inch web. Rotary letterpress is also used for long-run commercial, packaging, book, and magazine printing. Depending on the size and image elements in the printing, Letterpress printing machines exert variable amount of pressure on the substrate. To ensure that the impression pressure is just desirable close monitoring should be accomplished and certain adjustments must be made throughout the machine run. Major chemicals used in letterpress printing are very similar to those used in lithography. They include film developers and fixers, inks, and blanket and roller washes.

Application: Letter Press printing is used in commercial operation and specialty operations including imprinting, stamping, die cutting, numbering and others. Applications of this type of printing include business cards, company letterhead, proofs, billheads, forms, posters, embossing, hot leaf stamping and others.

(ii)Screen Printing- This technique, which gained popularity during the First World War for making banners and printing flags can be traced back to the beginning of the 19th century. The printing technique creates a sharp-edged image using a porous fabric and a stencil. The screen, a piece of porous, finely woven fabric including silk, polyester or nylon is stretched over a wooden or aluminum frame, is placed on top of a piece of paper or fabric. Areas of the screen are blocked off with a non-permeable material (a stencil). Ink is placed on top of the screen, and it is further spread evenly across the screen with a rubber blade. The ink passes through the open spaces in the screen onto the paper or fabric below; the screen is then lifted off and can be re-used after cleaning. For multiple colour screen printing on the same surface, the ink is allowed to dry and then the entire process is repeated with another screen and different color of ink.

Application: Screen-printing technique finds versatile applications used in different industries, from clothing to product labels, fabric labels to circuit board printing and others due to its compatibility with a variety of materials, including textiles, ceramics, metal, wood, paper, glass, and plastic.

(iii) Flexography Printing Process: Widely used to print packaging materials, this technique is used to print on a number of materials and products including corrugated boxes, folding cartons, multi-wall sacks, paper sacks, plastic bags made up of various materials such as plastic, paper and others. The printing plates are flexible and made of rubber or plastic. The inked plates with a slightly raised image are rotated on a cylinder, which transfers the image to the substrate. These machines involve simple operation and easy adaptation for the use of water-based inks and produce high quality, finer and clear impressions on different substrates.

These machines are popularly used for printing on materials including plastic, paper, foils, acetate films, which is generally carried out by the use of rubber/plastic printing plates. Flexographic machines, due to their high speed printing process, make use of fast-drying inks. These printing machines can print on a range of absorbent & non-absorbent materials and can print in continuous patterns.

In this technique, from a roll a substrate is fed into the machine and is finally pulled off through a series of printing units and as a consequence of this action the image is printed on the substrate. Each colour is provided by a single printing unit. It finds application in high quality packaging such as milk and beverage cartons, disposable cups, containers, self-adhesive labels, adhesive tapes, envelopes, newspapers, plastic bags and food and candy wrappers.

Types of Flexographic Printing Machine: (a) Stack Type Machine

(b) Central Impression Cylinder (CIC) Machine

(c) In-Line Machine

(d) Newspaper Unit Machine

(iv) Gravure Printing Process is used for long run printing with sharper, fine and clear images. The general operation involves image preparation, cylinder preparation, printing and finishing. It is a form of intaglio printing. The image is formed on a depressed or sunken surface. The image area consists of honeycomb shaped cells that are etched or engraved into a copper cylinder. As the cylinder rotates in an ink pan (bath of ink), any extra ink is wiped off the cylinder with the help of a steel doctor blade. As the substrate passes between the plate cylinder and the impression cylinder, ink is directly transferred to the substrate and image is formed.

Applications include printing magazines, greeting cards, gift-wraps, labels, flexible packaging, cartons and others.

Rotogravure Printing Machines operate at very high speeds and are used by a number of industries for printing magazines, advertising print materials, cards etc for printing job that are long running in nature and require sharper and finer prints & images on different materials including PET, PVC, PE and paper. These machines employ turret type unwinder and rewinder; automatic splicing and web discharging can also be done. To enhance the drying performance and minimize printing defects, these machines are equipped with high speed drying systems.

Applications: Greeting Cards, magazines, advertising materials including brochures, catalogs, flexible packaging, self-adhesive labels

Source “Polymer Science - Coatings and Adhesives and Technology of Printing Inks”